Let's Build A Mandolin (Page 18)

1 2 3 4 5 6 7 8 8a 9 10 11 11a 11b 12 12a 13 14 15 16 17 18 19 20

Last Modified - April 2012 (©Alan Dunwell 2012)

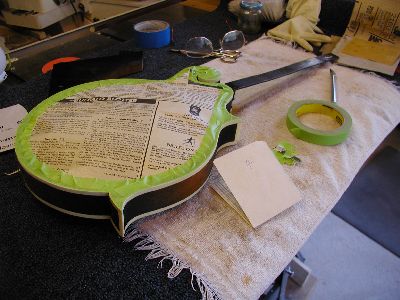

In Page 17 we got all the color on, now it is time to apply the actual finish. Mask up the neck again, this time just protecting the fretboard, nut slot, and butt end of the heel. Everything else will get lacquer or Tru-Oil. They both get the top masked off since I am going to french polish that, the rest gets lacquer.

Here we go. I shoot two double cross coats per day of the McFadden lacquer. I've now run out of the McFadden I had and will be using an old stash of the original Sherwin Williams instrument lacquer that I have. The double cross coat is where I shoot a coat going longwise and then hold it out to level and set, about a minute. Then I hold it vertically and shoot another coat going side to side, hold again to level and then let it cure for about an hour. Your time may vary, I'm in Colorado and the humidity here is often below 20% when I'm shooting. After it is cured a bit I do it all again and leave it overnight. On the neck I don't shoot the main straight part of the neck shaft with lacquer, just the headstock and heel parts. Between day one and day two I dry sand the lacquer to level it a bit, mostly just knock off any rough bits. Day two gets the same two double cross coat business and cure out over night. I've learned from experience that this lays down a finish that will end up about eight thousandths thick after curing out a couple weeks. This is still too thick but is just about right for the start of wet sanding later on. Final sanded lacquer is down around five or six thousandths thick.

Day three I use Tru-Oil on the back of the neck and build up just enough to protect the wood. I lay this on with a fad just like french polishing and fade it into the lacquer. The final step a day or so later is to burnish it with 0000 steel wool to get a nice fast finish.

I pull the top masking and do a french polish with the shellac that I mixed up earlier. With mandolins and the curved surfaces I find that I mostly do just long straight strokes without the circular finish business. This seems to give a better result. I mic with a vernier caliper through he F-hole and compare to the measurements I made the same way of the raw wood. The finish usually ends up about three to four thousandths thick with this method and leaves the top very responsive and with a high luster but not a lacquer-like gloss.

After the lacquer has cured out a good bit, usually left hanging for at least two weeks, I wet sand it back till it it is dead smooth. You can see that the finish really makes the grain pop at this stage. I buff it off and check for any areas that I missed and resand and buff as needed. Back and forth till I've got it all done. Not shown here but done at the same time is the neck. I don't buff the shaft where I did the Tru-Oil but once I have the lacquer all done I go back and blend the Tru-Oil and lacquer areas with the 0000 steel wool. I like to let everything sit after the buffing for a day or two to let it really harden up on the surface before I start mounting hardware. I know, we are getting close and it is a real temptation to get the hardware on, but it will leave dents in the lacquer at this stage. Be patient Grasshopper.

1 2 3 4 5 6 7 8 8a 9 10 11 11a 11b 12 12a 13 14 15 16 17 18 19 20