Red Henry Type Solid Mandolin Bridge Construction

© Alan Dunwell - 2002

Last Modified: 10/05/2011

The various projects here are listed in chronological order, so the most recent

is at the bottom. Jump links provided here in the text.

Red Henry started

looking into making mandolin bridges that are single piece rather than adjustable.

For the most part he started with a mandolin design bridge and has been working

towards a violin looking bridge. He has been posting up his results and those

of others on his web pages and on the CoMando mailing list and the designs and

development of this type of bridge is off to a good start. I was intrigued by

the idea. The first section below shows a

detailed process of the first two bridges that I built. A second

section below shows less detail but includes modifications or refinements

to the process on subsequent bridges built. Project Three

is a bridge similar in construction to the shedua one for Greg in the second

section. The KA Project is a mandolin I built for a

friends 50th birthday and put a shedula (shedua?) solid bridge on. With the

TR Project I've changed my design yet again. This reflects

Red's success with more recent multi-hole designs. This was for a mandolin for

Tom Risner in Texas and included an under-saddle type pickup.

The Initial Project:

Bridges #1 and #2:

For this project I was contacted by Brian Eyster, a local CoMando list member.

He had a K&G F5 mandolin by Mark Gresham and the bridge had been worked

sometime in the past and was no longer fitting well. We decided to try out Red's

ideas and see what difference it would make.

[Note: Images below are thumbnails low resolution images. For full resolution

detailed images double click on any thumbnail.]

Red Henry Type Mandolin Bridge Construction

|

I started out by looking at

the current designs of violin bridges with the idea of morphing them into

mandolin bridges. Here is a sample page from the International

Violin Company that shows their products. Also a great company for

other supplies. Notice that the basic design consists of a heart in the

center, some "egg shaped" holes that are cut with a horizontal slit. This

whole thing is designed to be able to not only flex vertically but to

also be able to twist as is needed in an instrument that is driven and

has a sound post. This may not be the exact design we want for a mandolin

that it plucked and doesn't have a post. |

|

Rather than make just one bridge I figured

that I might as well get a technique for making the bridges in larger

numbers. So I first cut out some blanks of Hard Maple and Shedua, a relative

of Bubinga. These are thicknessed to a little over 1/4". |

|

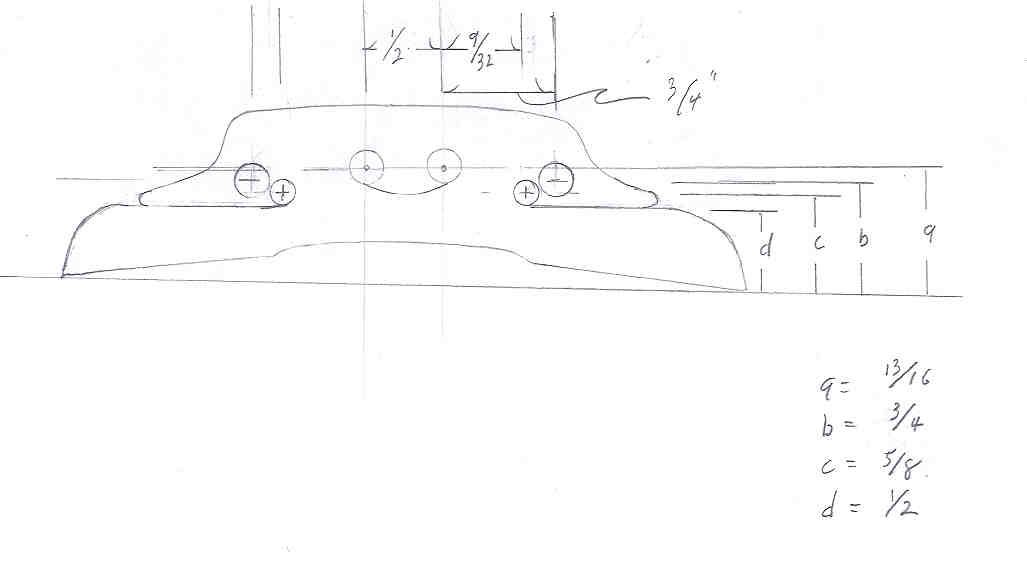

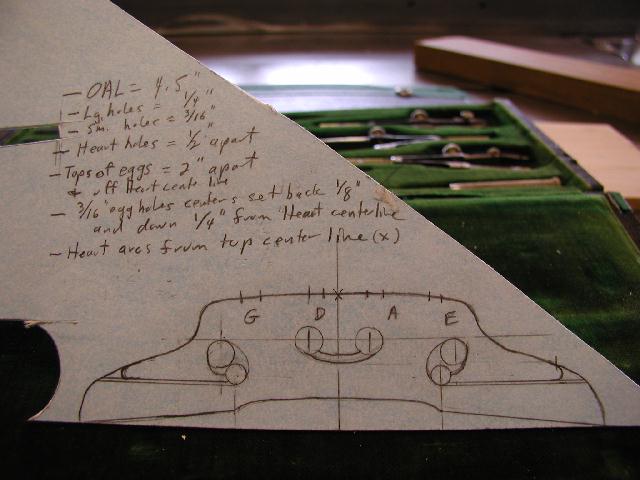

The Plan. Here is my first mutation of

the violin bridge into a mandolin bridge. I didn't bother to try to get

the feet cutaway and I sort of squashed the violin design down and made

it wider. I kept the heart and egg-shaped holes. I'm sure there must be

an official name for those but I call them the eggs. WARNING! Danger Will

Robinson!! Do _not_ use these dimensions they are flawed, see my later

design changes. |

|

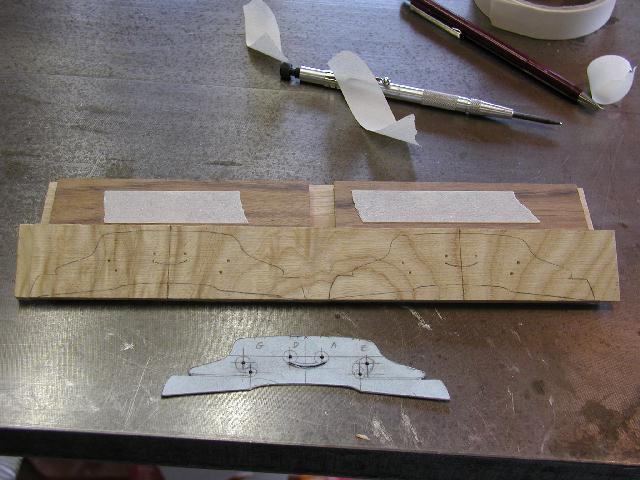

Here I've cut out my template and used

it as a pattern to trace on the top piece. Cheery little guys aren't they.

I used a spring loaded center punch to transfer the hole centers and then

highlighted them with the pencil. I then assembled the stack of pieces

with double-stick tape while aligning the bottom edges. |

|

Here I'm drilling out the holes with a

brad point bit. The brad point keys into the punched center marks and

cuts a clean hole. However, with the maple it still wanted to chip out

on the bottom side a bit. In the future I will also include a scrap piece

double stick taped to the bottom of the stack. Alternatively I could drill

a #50 guide hole first and then use the brad point bit from both sides

of the stack. I drilled the small 3/16" holes first and then drilled

the 1/4" holes which just cut into the 3/16" holes in the egg. |

|

Now I am rough sawing out the bridges.

There is a step skipped where I drew in the line for the horizontal slot.

I just used a straight edge aligned on the side notch areas, This just

touched the bottom of the egg holes. I am sawing to the top and leaving

the line on the bottom. I used a wave-kerf hacksaw type 1/4" blade and

that seemed to give a pretty good cut. My slot lines were a little

wobbly doing it freehand like this. I think in the future I'll make sure

that the line to cut is true to the bottom of the blank. Then I'll cut

out the profile but not the bottom part of the feet. That way I can use

a fence to get the slot lines true and later cut the bottom feet relief. |

|

I wanted the egg holes to look the same

so I didn't want to just file them out freehand. I made another template

and trued the eggs with a small french curve. I then aligned this on the

drilled holes and drew the curve to cut. |

|

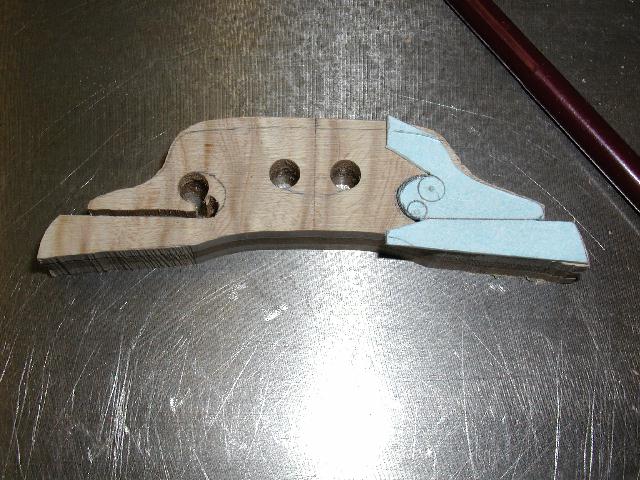

And now cut out the egg profiles and the

slit for the heart. I am using a regular coping saw as a fretsaw. The

teeth cut on the down stroke and I have a piece of wood in the vise that

has a central hole and a slit cut to the hole. This way I can thread the

saw blade into the heart hole, slip the blade through the slit in the

board in the vise and cut it true with even straight down strokes. You

can see that I have already smoothed them some on the belt sander. |

|

I then separated the individual bridge

pieces. Hmmmmmm, that double stick tape is _strong_! You can't just pry

them up or the wing parts will break off just like this. I had to use

a pallet knife to slip in and slowly ease each bridge free. I could have

also oozed some acetone in there to soften the glue but that makes quite

a mess to clean up after the fact. One might get away with using double

stick drafting tape since its glue is not so strong but the stacks might

come apart in the drill and saw process. Better to just be a bit careful

when taking them apart. Notice that this was one of the slab sawn pieces,

the quartered ones didn't have as much problem. I rough smooth the whole

thing but I don't do a real clean up yet. I want to file and thin it as

part of the tuning process. |

|

Fitting the feet to the top. There are

several schools of thought on this and both seem to work. Some hold the

bridge and wiggle it along the center line of the body. This way doesn't

have to worry about getting the fit of the top radius but you have a harder

time keeping it exactly aligned in the vertical without getting the bottom

of the feet "rounded" due to letting the bridge tip as you slide back

and forth. Sanding only on the push or the pull stroke helps this. I use

the side-to-side method. You can see some tape sticking out under the

sandpaper that indicate the bridge line. It is necessary to only slide

it a short distance, a 1/4" or less or else the tip ends of the feet will

not fit properly. I used 80 grit to rough it in with the side-to-side

and then 120 grit and along the axis to get the final fit. I just scribble

on the bottom with a pencil, take a couple strokes and check the bottom.

I can then use a scraper to shape it faster than the sandpaper. Then "repeat

as above" until the sanding indicates that it is true over the full foot

surface. One last swipe with a scraper to get off any sandpaper fuzz and

it is true. |

|

Now that the feet are fit to the top the

next step is to trim the top of the bridge down to set the action height.

To do this we need know where the fretboard height is. I use a simple

stick of wood with a 1/2-pencil taped to the bottom to strike a line across

the bridge. This marks the height of a line projected from the top of

the frets to the bridge. You need to use a long enough stick that it is

resting on the first frets too in case there is drop-away on the extension

or as in this case the extension is scooped. You really should adjust

the truss rod to get the neck flat too, but that is a bit much for what

we are doing here, the final fit will be done in a later step. |

|

Here is another shot of the marker stick.

Notice that this rig works for both flat and radiused fretboards. Now

that we have the height of the frets we measure up another 3/32" or so

and draw another line following the original. A quick hit on the belt

sander and we have it close enough to start the action and intonation

process. |

|

In order to string up we have to make nicks

in the bridge to hold the stings in place. If you have the old bridge

and are pleased with the spacing, just transfer the information to the

new one. If this is a new mandolin or you want to make corrections, just

position the bridge and use a long straight edge trued to each side of

the fretboard to mark the outside limits. Then figure the desired set

back and string pair separations and mark. Use an exacto razor saw or

similar to make the nick just deep enough to hold the strings. String

it up to pitch. |

|

Ugh Oh!!! Lookie dem feet! With string

pressure the cross slit has allowed the feet to wing up on the ends. This

bridge is firewood now. This is why I said earlier in the Plan section

not to use those dimensions. Back to the drawing board. Clearly I need

to leave more meat at the bottom so that the feet are stronger and/or

make the cross slot shorter. I had a stack that I hadn't already drilled

and cut out, so I just moved all the existing layout up 3/32" from the

bottom and repeated the above steps. [See the last section for my current

layout.] |

|

With the box strung to pitch I check the

string height at the 12 or 14th fret. A good average action is about three

or four sixty-fourths of an inch above the 12 fret. Start tall, you can

always lower if you want later. Using a razor saw and nut slotting files

I slowly work each string down to height. I lift the string out, cut a

little, lift it back in place, re-tune and check. This takes a while to

get right. (So why do them lute-in-ators get so much money for a simple

action job?<g>) |

|

Ok, the action height is right, but the

intonation is still trash. A couple comments on intonation. Your string

gauge, brand, age, orientation to the phases of the moon, etc. will change

the intonation. Decide on a brand and gauge at least and do the intonation

with a new set of strings. The process will kill them, but you want to

start fresh. To set the intonation you need to slowly file away the bridge

material to make the ramps. The break point will set the intonation. You

know from looking at other bridges that the general placement of the breaks

will be Forward, Back, Sort-of-Forward, Way-Back as counted from the high

E pair. Unless you have perfect pitch or perfect interval, use a tuner

that shows cents, preferably one with a sweep needle. Start with

the E string and pluck the open string, then pluck it's harmonic.

These should match. If they are off, slightly re-cut your notch with

a bit more back angle. Now compare the harmonic to the fretted 12th

fret note. It should be sharp. If not, slack the strings a bit, move

the bridge forward and re-tune to pitch until it is a few cents sharp.

You need to start sharp so that you can remove material to move the

break point back and increase the string length. Repeat for each string

till you have all the break points. Remove the bridge and ramp the backsides

at a lesser angle. Leave some meat at the top to support the strings,

especially the wound strings so they don't cut into the bridge wood

too much. |

|

Here is the rough completed maple bridge

sitting free. Notice that the bridge is not yet refined, it still has

rough edges. |

|

This the same for the shedua. |

|

Another shot of the shedua. [See the initial

notes below dated 9/30/2002 for Brian's assessment at this stage] |

|

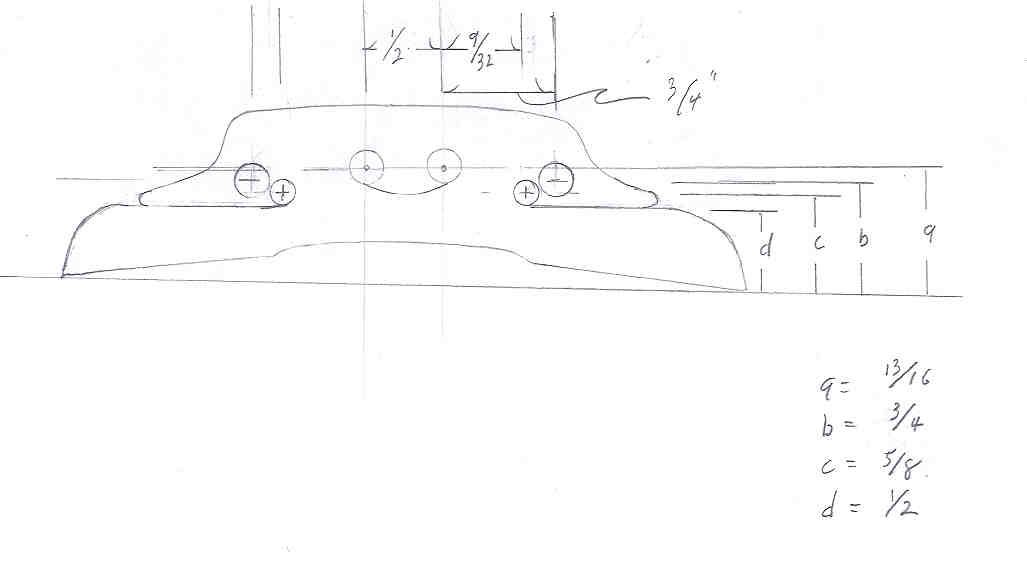

Here is the information on my current version.

This is a project in progress and this information will change over time.

Look at the "Last Modified" date at the top of this page to check for

changes. Notice that I have kept the heart area pretty much the same.

I moved the egg holes up and out a bit but also rotated the smaller

holes for the egg towards the center. This moves all the egg and side

slits up leaving a thicker leg NOTE: This has not yet been tried. Watch

for an update and information later. |

|

Brian returned the mandolin to me

after several weeks of play. He preferred the Shedua bridge because of

it's more woody sound but was still disappointed with the bass in both.

It just didn't seem to be very punchy on the low G strings. I started

trimming off the end of the bass side wing with a razor saw and this seemed

to bring up the bass a good bit. I kept trimming till I didn't hear a

change. I then tried this on the treble side and noticed a small reduction

in volume of the high E so I didn't remove any more. I then proceeded

to remove mass on the top of the bridge taking off any wood that didn't

need to be there for holding or intonating the strings. I then sanded

out to

600 grit and sealed the wood and finally applied lemon oil as a top protector.

Note that you need to mask off the bottom of the feet when doing any seal

or protection steps. You want raw wood on the bottom so it has a good

grip and fit. |

|

Here are the final bridges, Shedua on the

Left and Maple on the Right. Final weights are 6grams for the Maple and

7 grams for the Shedua. |

Play the heck out of it for a day or so and listen to it as you play. Then

remove the bridge and just clean it with jewelers files and sandpaper but don't

remove much wood. Restring and play again for a while and try to discern any

changes to tone. This will give you a feel for what wood removal will do. Try

modifications by filing the egg holes larger or by making the back side of the

bridge thinner near the top. You may be limited in this by the location of the

bass side strings. Minor dimension changes can make large tonal and volume changes.

I don't have a recipe yet for what area to remove to get what changes, any information

will be appreciated. It may be desirable to cosmetically stain the bridges or

seal them with a carnauba paste wax or other sealer (not on the feet bottoms

though) to help keep it looking clean and new.

NOTES:

9/30/2002

After I did this project up to the rough final stage I gave both bridges

to Brian to test. These were still in the unrefined state so that I could

make changes later if desired. He reported back with the following information.

In his comments the Bridge#1 is the Shedua, Bridge #2 is the Hard Maple.

"In general, I think the clarity and sustain were improved by both

bridges. They both are a bit louder than the adjustable bridge,

as

well. But the changes are not as dramatic as I had expected from

reading Red's descriptions. Neither bridge seemed to fill in

the

missing bottom-end on my mandolin. My mando body doesn't resonate

much

at low frequencies (based on singing into the f-holes), so I fear that

maybe my mando just doesn't have the bottom end for a bridge to bring

out.

...

Here are some more specific comments (Bridge #1 is the first bridge

you

had setup on monday, Bridge #2 is the maple one):

- Both bridges provide much more ring behind the bridge. I have

some

rubber grommets around somewhere, which I need to put on to control

that

a bit.

- Bridge #1 provided greater tone variance as I moved between the "sweet

spot" over the fingerboard extension (Matt Flinner tone) and the bridge

(Mike Marshall tone). This made the instrument a lot more fun

to play

and listen to.

- On Bridge #1 the "sweet spot" seemed to be closer to the nut than

with

the other bridges - almost above the extension.

- On bridge #1, I needed to adjust my double-stop tremolo technique

so

that the pick noise does not overwhelm the tone of the double-stop.

- On bridge #1, the G and D strings had better sustain than the E/A

strings. The E/A strings seemed more dampened.

- The new strings seemed to keep their new ring for twice as long as

usual with Bridge #1. I think this is because the sparkle I usually

associate with fresh strings seems to be brought out by Bridge #1.

- Bridge #2 had more volume than #1. This was noticeable immediately.

- Bridge #2 has a pronounced high frequency peak that gives it a lot

of

punch. This is similar to the adjustable ebony bridge, but more

pronounced.

- Bridge #2 did not have as much tonal variance between the bridge

and

the sweet spot.

- Bridge #2 had more even sustain across all the strings."

10/31/2002

I delivered the two completed bridges to Brian for testing. He has these

final comments on the shedua bridge:

"Perceived changes to the Shedua bridge:

- There is indeed a more well-defined bottom-end - not boomy or muddy,

but a more full-sounding attack on each note with more body. This was a

noticeable improvement from the previous version. This is not the big

resonating bottom-end boom that some mandolins have; it is more of a

clearly defined bottom-end punch that is balanced by the highs on each

individual note.

- Great balance of sparkle and punch when played close to the bridge. I

find myself playing down here a lot more often now, especially for

classical stuff and for bluesy down-stroke Monroe-style playing.

- I think there is less variance in the tone as you move the picking

position between the fretboard position and the bridge position. Part

of this is that the sweet spot moved towards the bridge. What is

interesting is that while it seems like there is now less tonal

variance, I think the range of desirable tone has been extended to cover

the entire playing area from bridge to fretboard. In the initial Shedua

bridge, I played mostly close to the fretboard extension to try to

balance the highs and lows on each note. Now I can play anywhere from

the bridge to the fretboard and get a desirable tone, although obviously

different depending on the position.

- Better balance and more even sustain across all the strings."

Further

Projects and Refinements:

10/20/2002 - The RMMGA Tx3 gathering - Bridge #3

I attended the third rec.music.makers.guitar.acoustic Texas gathering for a

weekend of fun, frolic, and general guitar and music debauchery. A good time

was had by all and as part of one lazy Sunday afternoon Greg Thomas, an RMMGA

and CoMando member, and I set to work on his Gibson AL5. This box already had

very good sound, particularly the bass side so we were just shooting to see

what would happen.

Greg Thomas Project

|

I brought a selection of bridge

blanks and we settled on trying the Honduran Rosewood one. This is the

same stuff that marimba bars are often made of. The blanks that I had

were slab sawn but had very good tap tone. This is the same stuff I use

for my guitar bridge plates. I used my refined template shown in the initial

process above that left more meat on the legs and that in addition to

the very hard nature of the HR made the legs quite firm. Greg's AL5 had

less height at the bridge, something that I didn't notice till I had already

fit the feet, so when I topped off the bridge it was getting pretty close

to the holes drilled. I was able to intonate it w/o cutting into the holes

though (photo at left) so we didn't scrap it. This bridge was also wider

at the feet, about 3/8" but I had tapered it on the fretboard side so

that it ended up about 1/4" at the top. The side towards the tailpiece

was flat and the feet were fit so that the flat side was at 90 degrees

to the top so that the strings break over it evenly. |

|

Here it is in the rough done stage. Greg

took it at this point to do the initial play-in and evaluation. One thing

we all noticed was that some of the really rich bass was missing. I did

this bridge before I learned about trimming the bass side wing to pull

out the bass. We will see if that holds true for this one when Greg brings

it back for final. |

|

|

|

|

NOTES:

11/23/2002 -The mandolin and bridge were returned to me by Greg and I did the

final trimming and fit and finish as shown above in the final images. The mandolin

was returned to Greg on 12/08/2002 and was generally met with pleasure. Greg has

taken it away to test and will provide final comments at a later date.

11/2003 - No further data has been received from Greg on this project so I'm

closing it out w/o.

KA Project

11/2003 - Bridge #4

This bridge was actually made at about the same time I made the one for Greg

Thomas and uses similar dimensions but I didn't get around to using it till

late in 2003. Karl Atkinson is a very old friend of mine and last year he had

his Really Old Guy 50th birthday. At this time I promised him a mandolin. It

has taken me until his 51st birthday to get around to finishing it in my schedule.

This bridge was designed to go onto a Dunwell Guitar mandolin that is is

a hybrid between

my Silvertip

and

Redbone

in that

it

has an Engelmann

top but Silver Maple back and sides. In the white, this mandolin sounded

a bit bright so I used the shedua for the bridge with the idea that it should

bring out the woody

bass

side of

the

engelmann.

I

also fitted a standard Randy Wood ebony adjustable to this mandolin.

Karl Atkinson Over-The-Hill Project

|

This is a shot from the

Bass side at the waist. |

|

Same but from the tail end. |

|

Direct from the tailpiece. Notice here

that it is not truly centered in that I have it all shifted just a skosh

to the bass side. This was an experiment in asymmetry to see if that

would improve the bass. As compared to the Randy Wood ebony adjustable

it does

seem to, but it is hard to decide whether that is a function of the shedua

or the shift. |

|

|

|

|

NOTES:

I intend to delivered it to Karl with the shedua bridge in place. My initial

impressions are that it was successful in taming the raw sound in the upper

register and

it gave the bass side a smoothness. The bass is not muffled in that the individual

notes are still clear but they seem to have an expanded envelope of sound such

that after the initial attack the note holds some of its volume before rolling

off to the sustain. This bridge makes the mandolin very loud. The ebony adjustable

seems loud but that is more of a vigorous attack with quick die-back of the

notes which seems more harsh at this point to my ear. Karl plays mostly bluegrass

but also does some performing in his local theater productions so we'll see

if he likes this sound or prefers the ebony. The action is deliberately high

at this point since I expect the top to relax some after finishing and the

resultant expansion. I will expect it back for final bridge adjustment and

final finish buffout.

TR Project

This project was a build for Tom Risner of Texas. He wanted to include a Pick-Up

The World pickup of some sort and we investigated various options. After chatting

with David Enke of PUTW we settled on putting in an under-saddle type pickup directly

in the bridge using a bone saddle on the top. This was sort of a learning process

and it went through several itterations. The overall design of the bridge is birds-eye

maple with 7 holes. This follows more recent work by Red

Henry where the design has multiple holes but no slotted wings. This gets

around the issues of compression and flex in the wing legs and fitting problems.

This mando was very responsive and I wanted a full-foot bridge on it rather than

two feet with a space between. This worked out well.

Tom Risner - Under-Saddle Pickup Bridge

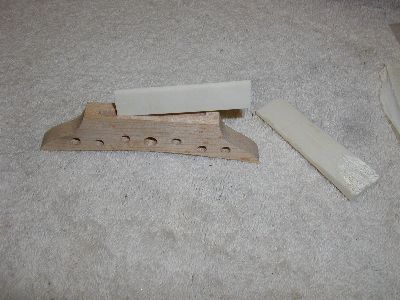

|

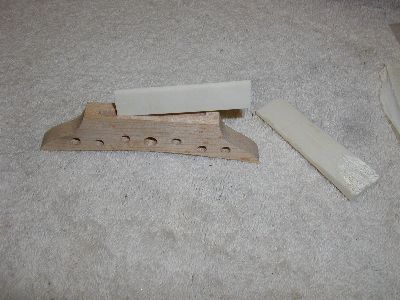

The initial design is very similar to my

earlier, I'm using my original template here for the profile. |

|

However, here I diverge a bit. I make the

profile on the side turn up rather than roll over and I mark on the top

in a bit to where the ends of the saddle will lie. |

|

Here you can see the saddle location all

laid out. I'm using pretty much the same as I would for a guitar but I also

checked with a Randy Woods mandolin bridge and measured the angle on that.

The slot is going to be 1/8" wide, this is just enough

to accommodate the wide stagger of the mandolin strings. |

|

I slot the bridge using a mill/drill cross

feed table bolted to my drill press. The bit is a 1/8" carbide bill

bit available from industrial supply housed such as MSC

Industrial. |

|

You can see this made a very clean slot with

a dead flat bottom. |

|

Now I drill the holes using brad-point bit.

I first drill with a very small bit and then drill with the brad-point using

the pilot hole as the guide. I drill half way through and flip it over and

drill to completion from the other side. This avoids any chipping or tear-out

as the bit breaks through. This hole pattern is my own take on Red's 9-hole

design. I wanted to leave some real estate to run the wire down w/o it showing

in the hole. This idea changes later on. |

|

Whack it out on the bandsaw. |

|

While it is still rough I go ahead and fit

the bridge to the top. This is a full single-foot design and I am using

carbon paper to mark where it is high. |

|

Once I can see the areas with carbon, I then

use a pocket knife with a curved blade to scrape that area away. This makes

a concave area on the foot. |

|

As it gets close you can see that it is just

marking the outer edges. It is still pretty rough here |

|

Getting closer now and I use the less

curved part of the knife so more of the bridge gets colored. I finalize

it by swapping out the carbon paper for some 120 grit garnet paper and

sand back and forth for about 1/4" wiggling in the same direction

as the strings run. Keep it very upright and since it is so close to a

true fit you don't need to press hard at all. Just "finit" the

process till you see the whole bottom is sanded true.

Once the saddle is fit to the top it is a good idea to re-check it's

overall height relative to the fretboard. If it is way too tall you may

want to sand the top edge down a bit and if necessary re-cut the slot

deeper. You want at least 3/8" - 1/4" of slot. |

|

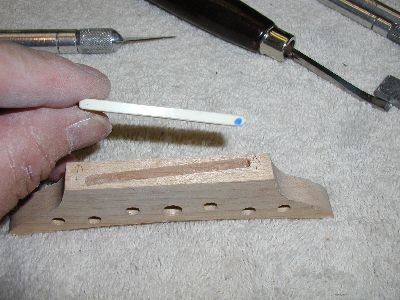

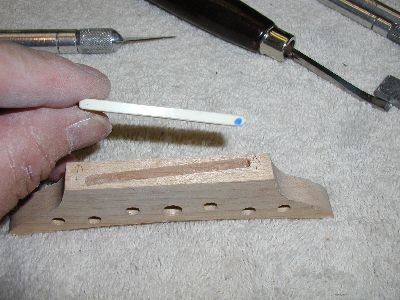

Now make the saddle. I use beef bones bought

from the pet store. I resaw them ont he bandsaw and then fabricate my nuts

and saddles from the good hard parts. |

|

Here you can see two blanks I've made. I

hand sand these on my stationary belt sander with 100 grit till they get

real close but are still a snug fit to the slot. user a vernier caliper

to check and keep them square side to side and end to end w/o any taper. |

|

When it is close I square it off in all directions

and flat the bottom true to the sides and ends. I select and mark the bottom

at this point. |

|

I now final fit the saddle rounding the ends

and sanding with 600 and 1000 grit papers on a flat surface till the saddle

just slips in w/o binding. I bevel off the bottom edges so they don't catch

and mark the treble side with a colored dot. At this point it is still left

well too tall, we will fit that later on. |

|

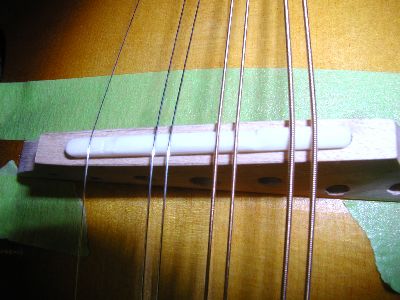

Here you can see it finalized and ready for

fitting the pickup. |

|

Here I'm following the initial plan and drilling

straight through just missing the holes as the route for the pickup wire.. |

|

Here you can see the pickup

in place. |

|

The maple bridge is pretty light but I decided

to take off the extra excess material that wasn't needed. So I sanded it

into a curved shape |

|

This shows the new sort of swoopy twist design.

|

|

An end view of the same. Next I string up,

lower the saddle as needed and find the proper position for the bridge to

accommodate the intonation settings. |

|

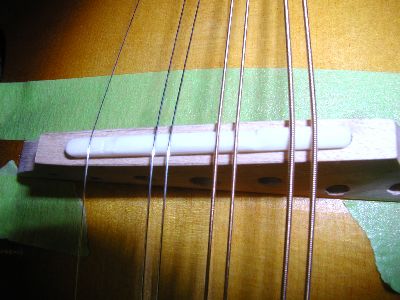

Here it is in place where I've notched the

saddle and set the intonation, just like you would for a guitar saddle.

Note the green tape holding/marking the bridge in place. There is some up

and down of the strings in this process and after locating the sweet spot

I didn't want to lose it. |

|

About this time I began to have second thoughts

about drilling the top. It occurred to me that it might be better to just

run the wire out one of the holes, under the pickguard and into the treble

F-hole. Tom also agreed that this was more to his liking. So I drilled the

treble side of the bridge into the outermost hole, beveled the edge of the

hole a bit and threaded the pickup wire down and out. Originally I thought

I'd have to cut the pickup to length but instead I just slipped the excess

down the other hole I drilled. |

|

This is then topped with the saddle. I strung

up and measured the action at the 12th fret and sanded off some of the bottom

of the saddle till I had the action I wanted. Then I threaded the wire into

the upper part of the treble F-Hole, secured it to the bottom side of the

mando with 3-M red "gummy bear" tape and pulled it out the lower

part of the F-Hole. |

|

Last was the installation of a Vintage

Jack which fits into the tapered end pin hole w/o modification. The wires

for that also go to the lower treble F-Hole and get soldered to the pickup

wires. The joined wires get pulled snug and gummy-beared to the bottom

side so nothing rattles. |

|

|

|

|

The sound turned out perfect. The full fit bridge gave a full spectrum of sound

with a good full bass but with a punchy treble. The maple bridge is several

grams less than the comparable Randy Woods bridge, even with the pickup and

bone in place. So there is excellent note separation and apparent brightness.

The bass side I'd have liked to be a bit stronger but that is the trade off

for the punchy treble that the owner preferred. I did attach some temporary

weights to the bridge and that did bring in the bass side more so that could

be changed later on if desired. However, this Adirondack top is pretty stiff

and I expect the bass side to come in more anyway as it breaks in. The amplified

sound is typical Pick-Up the World, dead on true to the acoustic sound w/o and

added flavours. Great products from David and Annie! Recommended.